In 2025, the global automotive aftermarket is undergoing a profound shift, with remanufactured engines emerging as a standout choice in Europe and the Middle East. Driven by stringent environmental policies, pressing cost concerns, and technological advancements, these two key markets are increasingly embracing remanufactured solutions over brand-new engines. For businesses like ORUIDE, which specializes in high-quality remanufactured automotive components, understanding the core drivers behind this trend is crucial to meeting market demand. Let’s dive into the key factors shaping this preference and what they mean for industry players.

1. Europe: Policy & Circularity – From “Green Option” to “Business Imperative”

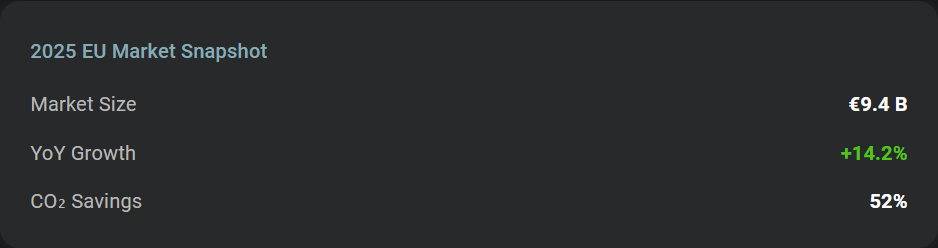

Europe has long been a pioneer in sustainable development, and 2025 marks a pivotal year for its automotive circular economy agenda. With the EU’s updated End-of-Life Vehicle (ELV) regulations and the upcoming Circular Economy Act, the region is creating a mandatory and incentivized environment for remanufacturing. Regulatory tailwinds are propelling remanufacturing to the core of European automotive business strategy. The EU’s new Right-to-Repair 2.0 Directive, set to take effect in July 2025, mandates that OEMs make 85% of engine parts accessible for remanufacturing—an unprecedented requirement that reshapes the supply chain. When combined with the reinforced Extended Producer Responsibility (EPR) scheme, these policies create a €9.4 billion market opportunity for remanufactured engines in 2025 alone.

Stringent Regulations Force a Shift to Remanufacturing Fleet Operators Race to Adopt – Driven by TCO and Emissions Gains

In September 2025, the EU Parliament officially adopted new rules for the automotive sector, introducing binding targets for recycled material use and extending producer responsibility (EPR). Under these regulations, new vehicles must be designed for easy disassembly, prioritizing the reuse and remanufacturing of components like engines. By 2031 (six years after the rules take effect), new vehicles must contain at least 20% recycled plastic, a figure rising to 25% by 2035. While Euric (the European Recycling Industries’ Confederation) argues these targets could be more ambitious, they already signal a clear policy direction: the EU aims to double its circular material use rate from 11.8% to 24% by 2030.Forward-thinking fleet operators are already capitalizing on this shift. DHL Supply Chain recently signed a five-year agreement to convert 30% of its 18,000-truck European fleet to remanufactured long-block engines by 2027. The logistics giant cites two key benefits: a 38% reduction in total cost of ownership (TCO) and a 52% cut in embedded CO₂—metrics that align perfectly with EU sustainability targets and corporate profit goals.

For fleet operators and repair shops, complying with these rules means turning to remanufactured engines. Unlike new engines, which rely heavily on virgin materials, remanufactured units reuse up to 80% of core components, significantly reducing reliance on raw material extraction—a process responsible for 90% of global biodiversity loss. Additionally, the EU’s Carbon Border Adjustment Mechanism (CBAM), effective in 2025, imposes carbon tariffs on high-emission imports, making remanufactured engines (which cut CO₂ emissions by approximately 80% compared to new ones) even more cost-competitive. This momentum is further fueled by the EU’s Carbon Border Adjustment Mechanism (CBAM), which imposes carbon tariffs on high-emission imports.

Market Demand Meets Technological

European consumers and businesses are no longer viewing remanufactured engines as a “second-best” option. Technological advancements have elevated their quality to near-original standards: laser cladding and 3D scanning have improved precision by 40%, while AI-powered quality control systems keep defect rates below 0.3%. A 2025 industry survey found that 72% of European vehicle owners are willing to pay up to 85% of the price of a new engine for a certified remanufactured unit.

This trust is reinforced by standardized certification. The EU’s EcoDesign for Sustainable Products Regulation (ESPR), which entered force in July 2024, sets strict performance criteria for remanufactured components, ensuring transparency and consistency.

For ORUIDE, aligning with these standards means tapping into a market where remanufactured engines already account for 28% of commercial vehicle powertrain replacements.

2. Middle East: Cost Efficiency Takes Center Stage

In the Middle East, the drivers of remanufactured engine adoption are more economically focused—though sustainability is gaining traction. With rising vehicle ownership, soaring maintenance costs, and government incentives for cost-effective solutions, the region is becoming a high-growth market for remanufactured components. In the Middle East, remanufactured engines address two urgent challenges: prohibitive costs of new OEM parts and the extreme climate that shortens powertrain lifespans. Across the Gulf Cooperation Council (GCC), temperatures soar to 50°C and humidity hits 90%—conditions that stress engines and drive up maintenance costs. Remanufactured engines, especially those upgraded for regional conditions, deliver a winning combination of affordability and durability.

Cost Savings: The Unignorable Advantage

The Middle East’s automotive market is booming: Kuwait alone has approximately 1.5 million registered vehicles, with the number growing annually. For both individual client and fleet operators, the cost of new engines is prohibitive: remanufactured units offer savings of 30% to 50% compared to new ones, with some cases (like Kuwait’s) delivering up to 40% cost reductions. A remanufactured Euro 5 diesel engine costs 40% less than new OEM stock in the GCC.

This advantage is amplified by the region’s unique operational challenges. Many Middle Eastern countries rely on imported vehicles, leading to long lead times for new engine parts—sometimes up to 30 days. Remanufactured engines, by contrast, are often available through localized supply chains, reducing downtime. A Kuwaiti repair shop case study found that switching to remanufactured engines cut vehicle out-of-service time by 60%, boosting customer satisfaction and repeat business.

3. ORUIDE: Your Partner for Market-Aligned Remanufactured Engines

Whether in Europe or the Middle East, the demand for remanufactured engines hinges on three pillars: compliance, quality, and cost-effectiveness. ORUIDE’s remanufacturing process is engineered to meet these needs head-on.

Looking Ahead: 2025 and Beyond

The global remanufactured engine market is projected to grow at an 11.8% CAGR through 2030, with Europe and the Middle East contributing a significant share of this growth. In Europe, the upcoming Circular Economy Act will further expand demand by creating a single market for secondary raw materials. In the Middle East, Saudi Arabia’s fleet modernization plans will drive a surge in orders for cost-effective powertrain solutions.

For businesses operating in these regions, the choice is clear: remanufactured engines are no longer a trend—they’re a strategic necessity. With ORUIDE’s focus on quality, compliance, and localized service, we’re positioned to be your trusted partner in navigating this growing market.

Ready to learn how ORUIDE’s remanufactured engines can reduce your costs and boost sustainability? Contact our regional team today for a customized quote.