On December 30, 2025, a delegation from the National Remanufacturing Association conducted a year-end work inspection at Oruide Company, a leading enterprise in China's automotive parts remanufacturing industry.

The inspection aimed to assess compliance with industry standards, technological advancement, and management practices, as part of the association's efforts to promote high quality development of the remanufacturing sector, a key component of the national circular economy strategy. After a comprehensive review of production processes, management systems, and product quality, the delegation highly recognized Oruide's achievements in standardized operations, technological innovation, and quality control, affirming the company's leading role in advancing the industry's sustainable development.

Delegation's Inspection: A Comprehensive Review of Standardized Operations

Led by the association's vice president, the delegation was warmly received by Oruide's senior management team. The inspection began with a detailed presentation by Oruide's technical director, who outlined the company's development journey, core business layout, and year-end work progress. The report focused on three key areas: strict adherence to the "Interim Measures for the Regulation and Administration of Automobile Parts Remanufacturing," continuous optimization of remanufacturing processes, and breakthroughs in core product research and development.

Subsequently, the delegation visited Oruide's intelligent production workshop, quality testing center, and parts recycling and storage warehouse. During the site inspection, the team closely observed the entire remanufacturing process from the inspection and disassembly of used engine cores, cleaning and repair of key components to precision machining, assembly, and final performance testing.

The delegation paid special attention to Oruide's advanced surface treatment processes, and quality monitoring systems, taking notes and asking in-depth questions about technical parameters and operational standards.

In the final feedback session, the delegation commended Oruide for its rigorous implementation of industry regulations and standardized management systems. "Oruide has established a complete quality assurance system covering the entire industrial chain, from raw material procurement to product delivery," noted the delegation leader. "The company's emphasis on technological innovation and environmental protection aligns perfectly with the development direction of the remanufacturing industry, setting a benchmark for peer enterprises."

The delegation also provided constructive suggestions for future development, encouraging Oruide to further expand international cooperation and enhance brand influence in the global market.

Oruide's Core Products: Remanufactured Engines with OEM-Level Quality

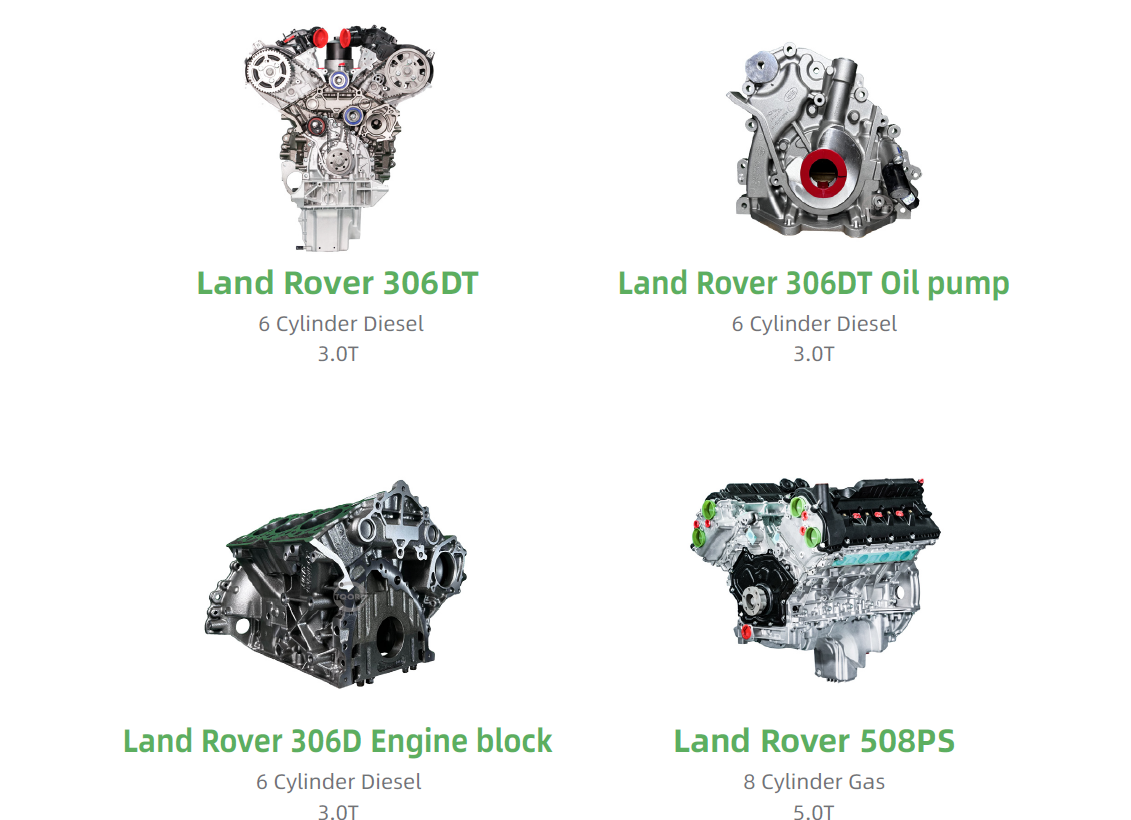

As a professional manufacturer specializing in the remanufacturing of high-end automotive engines and core components, Oruide has focused on technological innovation and quality improvement since its establishment. The company's product portfolio covers remanufactured engines for mainstream luxury and mid-to-high-end brands, with its Land Rover and BMW remanufactured engines standing out as flagship products that have gained widespread market recognition.

Land Rover Remanufactured Engines: Restoring Performance with Advanced Technology

Oruide's remanufactured engines for Land Rover models including the Ingenium series 2.0T four-cylinder and 3.0L inline-six engines—are built on the original manufacturer's technical standards, combined with advanced remanufacturing technologies to achieve performance levels comparable to new engines. The 3.0L inline-six remanufactured engine, in particular, adopts a modular design inherited from Land Rover's original Ingenium platform, retaining key technological advantages such as a 48V mild hybrid system and electric supercharger.

After remanufacturing, the engine's maximum output power reaches 294kW (394 hp) and peak torque hits 550 N·m, fully meeting the EU6b emission standard. Through precision machining and optimization of the combustion system, the engine's thermal efficiency is significantly improved, with a brake specific fuel consumption of 229 g/kWh—achieving better fuel economy than many original engines. The electric supercharger, which can reach 65,000 rpm in just 0.5 seconds, effectively eliminates turbo lag, providing instantaneous power response and a smooth driving experience .

Every Land Rover remanufactured engine undergoes over 200 strict quality inspections, including dimensional accuracy testing, material performance analysis, and 100-hour continuous operation trials. The company uses original or OEM-certified parts for key components such as pistons, crankshafts, and bearings, ensuring the engine's reliability and durability. Customers who choose Oruide's Land Rover remanufactured engine not only enjoy a cost advantage of 30-50% compared to purchasing a new engine but also receive a 2-year/100,000-kilometer warranty, providing comprehensive after-sales protection.

BMW Remanufactured Engines: Precision Engineering for Driving Excellence

Oruide's BMW remanufactured engines cover popular models such as the N20, N55, B48, and B58 series, targeting the needs of both individual car owners and professional repair shops. These engines are remanufactured using a "performance enhancement" approach, going beyond simple repair and restoration to optimize key components and improve overall performance.

The B48 2.0T remanufactured engine, for example, features upgraded fuel injectors with an injection pressure of 250 bar and enhanced ignition coils with an energy output of 108 megajoules which significantly improving combustion efficiency and power output. The engine's cylinder block and cylinder head are subjected to precision grinding and laser cladding technology to restore dimensional accuracy and enhance wear resistance. After remanufacturing, the engine's power and torque are increased by 5-8% compared to the original, while fuel consumption is reduced by 10%, achieving a balance between performance and environmental protection.

Oruide has established a specialized quality control team for BMW remanufactured engines, composed of engineers with over 15 years of experience in BMW engine maintenance and remanufacturing. Each engine undergoes a comprehensive performance test on a professional test bench, simulating various driving conditions. Only engines that meet or exceed BMW's original technical standards are allowed to leave the factory, ensuring that customers receive products with consistent quality and performance.

Committed to Sustainable Development: Leading the Remanufacturing Industry Forward

The recognition from the National Remanufacturing Association is both an affirmation of Oruide's past achievements and a motivation for future development. As a key enterprise in China's remanufacturing industry, Oruide has always adhered to the concept of "resource recycling and sustainable development," contributing to the reduction of resource consumption and environmental pollution.

In the future, Oruide will continue to invest in technological innovation, focusing on the research and development of remanufacturing technologies for new energy vehicle components and intelligent manufacturing systems. The company plans to strengthen cooperation with international remanufacturing enterprises and research institutions to introduce advanced technologies and management experience, further improving product quality and market competitiveness. At the same time, Oruide will actively respond to the call for green development, expanding its product range to cover more automotive brands and models, and striving to become a global leader in the remanufacturing industry.

The successful conclusion of the year-end inspection by the National Remanufacturing Association has laid a solid foundation for Oruide's future development. With its commitment to quality, innovation, and sustainability, Oruide is poised to make greater contributions to the development of the global remanufacturing industry, providing customers with high-quality, cost-effective remanufactured products and promoting the realization of a circular economy.

Hot News

Hot News2026-01-09

2025-12-03

2025-10-18

2025-10-15

Copyright © Miracle Oruide (guangzhou) Auto Parts Remanufacturing Co., Ltd. - Privacy Policy