Global aftermarket supply chains have long been plagued by parts shortages, a challenge exacerbated by geopolitical tensions, raw material scarcity, and disruptions in manufacturing and logistics networks.

For industries reliant on heavy machinery and vehicles from automotive and construction to agriculture and logistics, these shortages translate to costly downtime, delayed operations, and lost revenue. In this context, remanufactured engines have emerged as a critical lifeline, stabilizing supply chains while delivering economic and environmental benefits. Oduide, a leader in the remanufacturing sector, stands at the forefront of this solution, leveraging advanced technology and global reach to fortify aftermarket resilience.

Remanufactured engines are far more than "refurbished" units, they undergo a rigorous, OEM-aligned process that restores used engines (or "cores") to performance levels equal to, or even exceeding, new engines. The process—encompassing disassembly, precision cleaning, component inspection, reconditioning or replacement of worn parts, reassembly, and rigorous testing, ensures reliability while reducing dependence on new raw material extraction and manufacturing.

During parts shortages, this circular approach becomes invaluable: remanufacturers like Oduide repurpose existing cores, bypassing the bottlenecks of new part production and delivering ready-to-use engines to markets in need.

The role of remanufactured engines in stabilizing global aftermarket supply chains is multifaceted. First, they enhance supply availability. Unlike new engines, which may face months of production and shipping delays, remanufactured engines are often available in shorter lead times, thanks to streamlined reverse logistics and in-house production capabilities. Oduide’s global network of core collection centers and production facilities—strategically located across key markets—ensures that it can source, remanufacture, and deliver engines to customers worldwide, even amid regional supply disruptions. This accessibility helps aftermarket distributors and end-users avoid prolonged downtime, a critical advantage when every day of inactivity impacts the bottom line.

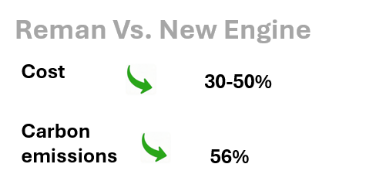

Second, remanufactured engines drive cost efficiency, a key consideration for businesses navigating the financial pressures of parts shortages. New engines and critical components often come with premium price tags, especially during supply crunches when demand outstrips availability. Remanufactured engines, by contrast, typically cost 30-50% less than new units while offering comparable warranty coverage. Oduide further amplifies this value by adhering to strict quality control protocols—each engine undergoes dynamic testing and performance validation to meet OEM standards—backed by a comprehensive warranty that instills confidence in customers. This combination of affordability and reliability makes remanufactured engines a pragmatic choice for businesses seeking to maintain operations without overstretching budgets.

Sustainability is another compelling benefit that aligns remanufactured engines with global trends toward circular economies. The remanufacturing process reduces carbon emissions by up to 56% compared to new engine production, as it minimizes the energy and resources required for raw material extraction and processing. As governments and industries tighten environmental regulations, Oduide’s commitment to sustainable remanufacturing not only supports supply chain resilience but also helps customers meet their ESG goals. This dual value—operational and environmental—positions remanufactured engines as a forward-thinking solution for modern supply chains.

Oduide’s strength in this space lies in its technical expertise and customer-centric infrastructure. The company keeps exploring the application of advanced technologies, such as precision machining and AI-driven quality inspection, to ensure consistent, OEM-grade performance across its remanufactured engine lineup. Its team of certified engineers specializes in a wide range of engine types, from gasoline to diesel, enabling Oduide to cater to diverse aftermarket needs. Moreover, Oduide’s robust reverse logistics system simplifies core returns for customers, further integrating sustainability into the supply chain while ensuring a steady flow of materials for remanufacturing.

In an era where supply chain uncertainty has become the norm, the importance of remanufactured engines cannot be overstated. They not only mitigate the impact of parts shortages but also deliver long-term value through cost savings and sustainability. Oduide’s leadership in this sector—powered by global reach, technical excellence, and a commitment to quality—makes it a trusted partner for businesses seeking to fortify their aftermarket supply chains. As the global auto parts remanufacturing market continues to grow at a CAGR of 7%, reaching an estimated $27.21 billion by 2030, Oduide is well-positioned to lead the charge, ensuring that global aftermarket supply chains remain resilient, efficient, and sustainable.

For businesses navigating parts shortages and seeking reliable, cost-effective engine solutions, Oduide’s remanufactured engines offer a proven path forward. Contact Oduide today to learn how our expertise can support your operational continuity and supply chain resilience.