In the automotive aftermarket, few terms are used as loosely—and misunderstood as deeply, as engine remanufacturing and engine reconditioning or rebuilt.

They are often treated as interchangeable, yet in practice they represent two fundamentally different technical approaches, quality levels, and risk profiles.

This confusion does not only affect terminology. It directly influences engine performance, service life, warranty exposure, and even regulatory compliance in certain markets. For fleet operators, insurers, distributors, and workshops, understanding the difference is not optional—it is operationally critical.

This article provides a structured, neutral explanation of how remanufacturing and reconditioning differ, based on industry practices, technical standards, and real-world application.

1. Why the Terms Are Commonly Confused

Tere are three main reasons why remanufacturing and reconditioning are frequently mixed up:

- Language ambiguity

Terms such as reman, recon, rebuilt, and refurbished are used inconsistently across regions and marketing materials. - Uneven regulatory definitions

Some markets clearly define remanufacturing standards, while others rely on self-declared terminology. - Surface-level similarities

Both processes involve disassembly, cleaning, and reassembly, which can appear similar without deeper technical inspection.

Despite these overlaps, the underlying philosophy and execution of the two processes are substantially different.

2. What Is Engine Reconditioning?

Engine reconditioning / rebuilt (often called rebuilding or recon) is typically a repair-oriented process.

A reconditioned engine usually undergoes:

- Partial or full disassembly

- Basic cleaning

- Visual inspection of components

- Replacement of only visibly damaged or failed parts

- Reassembly without full-system recalibration

The primary goal is to restore functionality, not to restore the engine to its original manufacturing specification.

Key Characteristics of Reconditioning

- Component reuse is maximized

- Dimensional tolerances are not comprehensively restored

- Performance consistency varies from unit to unit

- Process depth depends heavily on individual workshop capability

Reconditioning can be appropriate for short-term cost control or limited-use applications, but it offers no systematic guarantee of long-term reliability or uniform quality.

3. What Is Engine Remanufacturing?

Engine remanufacturing is a standard-driven industrial process, not a repair activity.

A remanufactured engine is restored to:

- Original OEM specifications, or

- A defined, audited remanufacturing standard recognized by the industry

This requires full process control, mandatory component replacement, and documented verification at each critical stage.

Core Principles of Remanufacturing

- All critical dimensions are restored within OEM tolerance ranges

- Wear-prone and safety-critical components are replaced regardless of visible damage

- Performance parameters are verified, not assumed

- Each engine follows a repeatable, traceable process

The objective is not merely to make the engine work, but to ensure predictable performance, durability, and interchangeability, comparable to a new OEM engine.

4. Process-Level Differences: Remanufacturing vs Reconditioning

Disassembly and Cleaning

- Reconditioning: Cleaning is primarily cosmetic or functional.

- Remanufacturing: Components undergo intensive cleaning processes to remove oil residue, carbon deposits, and contaminants from all internal passages.

Inspection and Measurement

- Reconditioning: Visual checks dominate; dimensional inspection is limited.

- Remanufacturing: All key components are measured against OEM tolerances, including:

- Crankshaft journals

- Cylinder bores

- Connecting rods

- Bearing seats

- Component Replacement

In a true remanufacturing process, industry standards typically require mandatory replacement of:

- Pistons and piston rings

- Piston pins

- Main and connecting rod bearings

- Bushes

- Gaskets and seals

- Timing chains or belts

- Core plugs

- Oil filters

Reconditioning replaces parts only when failure is obvious, which introduces variability and hidden risk.

5. Machining, Calibration, and Quality Control

Machining and Rework

Remanufacturing includes controlled machining operations such as:

- Cylinder honing to restore surface finish

- Crankshaft grinding within OEM limits

- Oil passage deburring and reconditioning

- Crack testing of structural components

These steps are rarely systematic in reconditioning workflows.

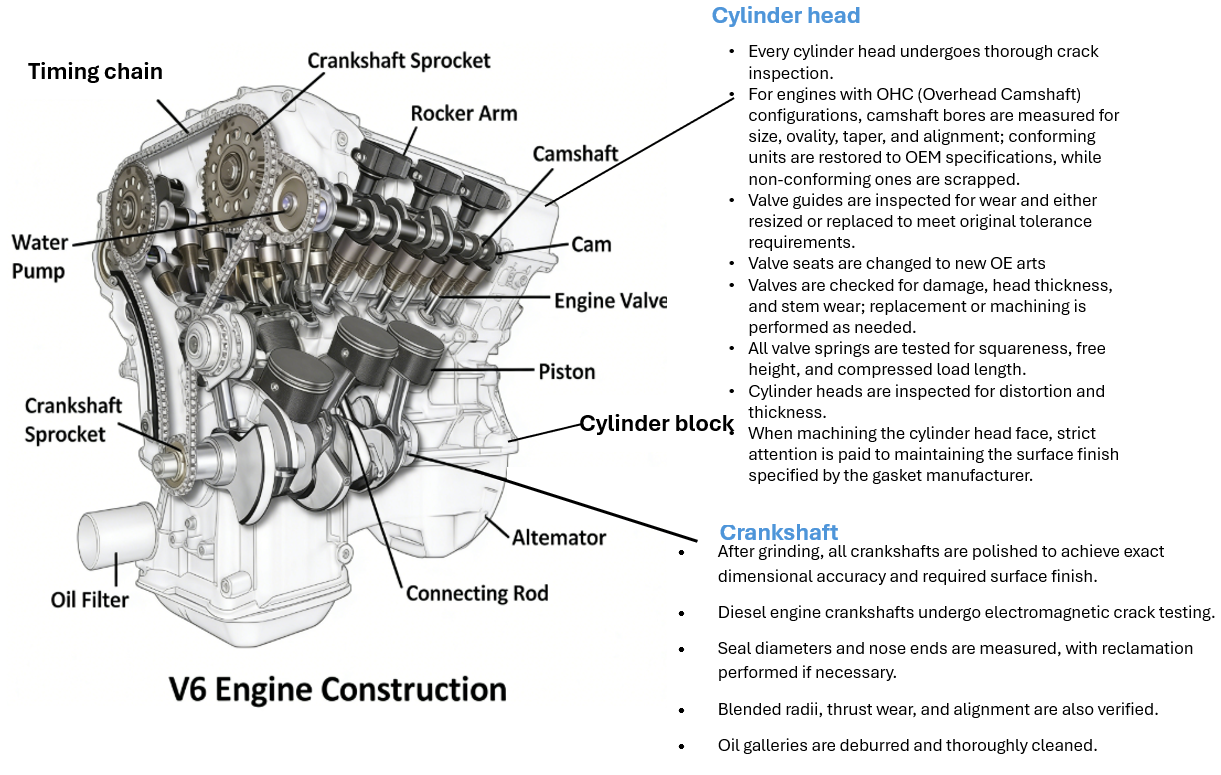

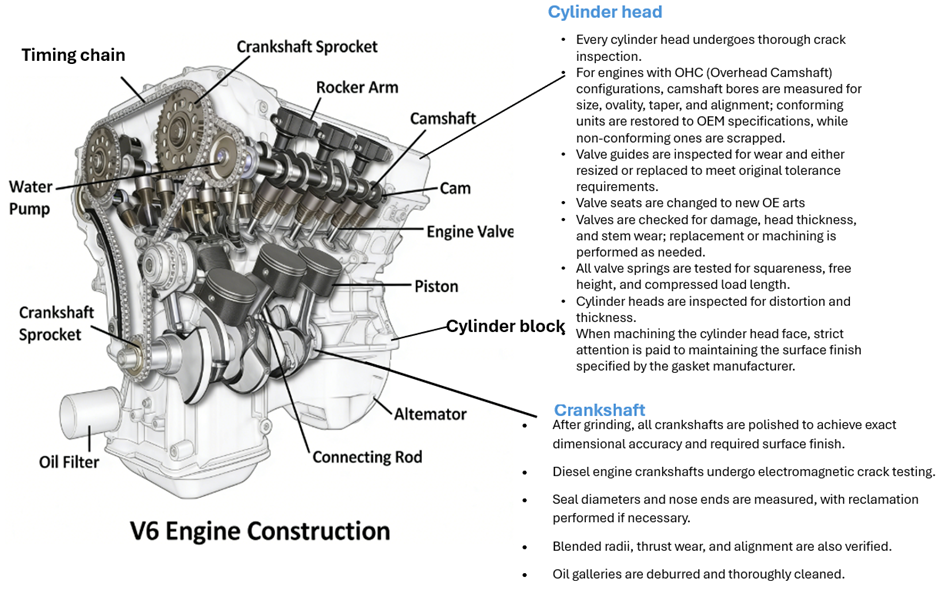

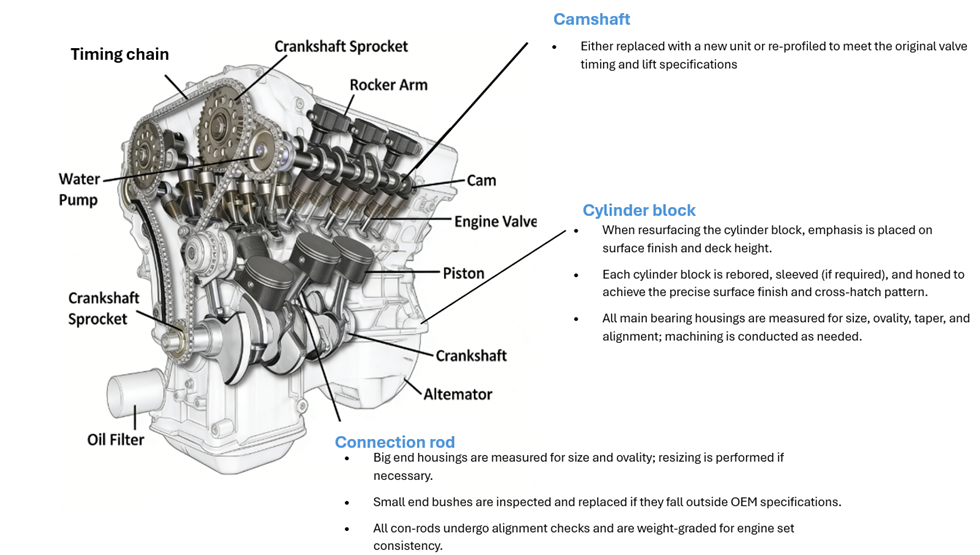

Example: Key engine subsystems subject to inspection, machining, and verification during a standardized remanufacturing process.

Assembly Control

During remanufacturing:

- All clearances, end floats, and torque values are verified

- Assembly follows standardized work instructions

- Deviations trigger corrective actions, not acceptance

Reconditioning often relies on technician experience rather than documented process control.

6. Testing and Traceability

Testing represents one of the most decisive differences.

Reconditioned Engines

- May receive basic functional checks

- Often lack standardized test documentation

- Traceability is limited or nonexistent

Remanufactured Engines

Typically undergo:

- Oil pressure testing

- Compression testing

- Leak testing

- Functional verification in controlled test cells

All results are recorded and linked to a unique engine serial number, enabling full traceability across the engine’s lifecycle.

7. Standards, Compliance, and Warranty Implications

Only engines produced under recognized remanufacturing standards can legitimately be classified as remanufactured.

These standards govern:

- Process sequence

- Mandatory component replacement

- Measurement criteria

- Testing requirements

- Documentation and auditability

From a commercial perspective, this has direct implications for:

- Warranty duration and enforceability

- Fleet reliability metrics

- Insurance risk assessment

- Regulatory compliance in certain regions

Engines that do not meet these criteria, regardless of marketing language, remain reconditioned products.

8. Practical Implications for Buyers and Operators

Choosing between remanufacturing and reconditioning should be a risk-based decision, not a terminology-based one.

- Reconditioning may suit:

- Low-mileage usage

- Budget-constrained scenarios

- Short-term operational needs

- Remanufacturing is typically preferred for:

- Fleets and commercial vehicles

- Insurance-backed repairs

- Long-term cost-of-ownership optimization

- Applications requiring performance consistency

Understanding the distinction allows buyers to align technical expectations with operational reality.

9. Who Should Contact Us

This article is intended to clarify technical distinctions—not to position a product.

That said, certain stakeholders may find it useful to engage further when these distinctions have direct operational consequences.

You may benefit from contacting us if you are:

- Fleet operators or mobility providers

who require consistent engine performance, predictable lifecycle costs, and enforceable warranty structures across multiple vehicles. - Insurance companies or claims management partners

involved in specifying replacement engines where process traceability, test documentation, and liability control matter. - Automotive aftermarket distributors or wholesalers

seeking to differentiate between reconditioned and genuinely remanufactured engines at a technical and contractual level. - OEM-aligned service networks or professional workshops

that must align engine sourcing decisions with remanufacturing standards, regulatory expectations, or long-term reliability targets.

Conversely, if your primary objective is short-term cost reduction without standardized performance requirements, reconditioned engines may be sufficient, and further technical alignment is likely unnecessary.

Our role, where relevant, is to support informed decision-making around remanufactured engines produced under controlled, auditable processes, rather than to promote remanufacturing as a universal solution.

10. Where Professional Remanufacturers Fit In

Professional engine remanufacturers operate within these standardized frameworks, combining:

- OEM-aligned technical requirements

- Certified quality management systems (such as ISO 9001)

- Documented testing and traceability

- Repeatable, auditable production processes

Engines produced under such conditions represent a fundamentally different category from reconditioned or rebuilt units, regardless of outward appearance.

Final Thoughts

The difference between remanufacturing and reconditioning is not semantic—it is structural, technical, and measurable.

A remanufactured engine is defined by process discipline, standards compliance, and verified performance, while reconditioning remains a repair-focused activity with inherently variable outcomes.

For decision-makers across the automotive value chain, clarity on this distinction is essential to controlling cost, risk, and reliability.